Analyze the Molding Technology Process of Four Types of 3D Printing

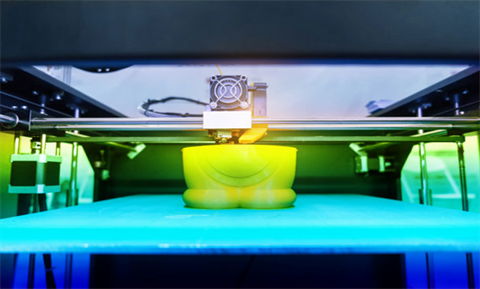

Fused deposition modeling (FMD)

FMD may be the most widely used process at present, and many consumer-grade 3D printers use this process because it is relatively easy to implement.

The FMD heating head heats the hot melt material (PLA, ABS, PETG) to a critical state, making it appear semi-fluid.

Then the heating head will move along the two-dimensional geometric trajectory confirmed by CAD under the control of the software.

At the same time, the nozzle will squeeze out the material in the semi-fluid state, and the material will instantaneously solidify to form a thin layer with a contour shape.

Stereolithography (SLA)

The basis of this process is a photosensitive resin that can produce polymerization under ultraviolet light irradiation. Like other 3D printing processes, SLA light curing equipment will also slice the 3D digital model of the object before it starts to "print" the object.

Then, under computer control, the ultraviolet laser scans the liquid resin point by point along the contour of each layered section of the part. The scanned resin thin layer will undergo polymerization reaction, gradually forming a line from the dots, and finally a solidified section of a thin layer of the part is formed, while the unscanned resin remains in the original liquid state.

When one layer is cured, the lifting table moves a distance of one layer thickness, and a new layer of liquid resin is covered on the surface of the cured resin of the previous layer for scanning and curing again. The newly cured layer is firmly bonded to the previous layer, and so on, until the prototype of the entire part is completed.

The characteristics of the SLA process are that it can present higher precision and better surface quality, and can manufacture parts with particularly complex and delicate shapes.

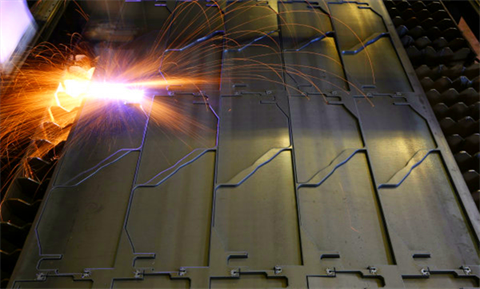

Selectivelasersintering(SLS)

The SLS process has similarities with the SLA light curing process. That is, it is necessary to use a laser to solidify the substance into a whole. The difference is that the SLS process uses an infrared laser beam, and the material is changed from photosensitive resin to powder of plastic, wax, ceramic, metal or their composites.

First, a thin layer of raw material powder is not spread on the worktable, and then the laser beam under the control of the computer passes through the scanner at a certain speed and energy density to scan according to the two-dimensional data of the layer.

The powder scanned by the laser is sintered into a solid layer of a certain thickness, and the unscanned area remains loose powder. One layer is scanned, and then the next layer is scanned.

The workbench is raised and lowered according to the thickness of the object's cut layer, the powder spreading roller spreads the powder again, and then starts scanning of a new layer. This is repeated until all levels have been scanned. Remove excess powder, and then after appropriate post-processing such as grinding and drying, the parts can be obtained.

3D printing(3DP)

Also known as bonded jet, inkjet powder printing. The working method of this 3D printing technology is the closest to the traditional two-dimensional inkjet printing. Like the SLS process, the 3DP technology also makes parts by bonding powder into a whole, but it is not bonded by laser melting, but by the adhesive sprayed from the nozzle to complete the bonding work.

Under the control of the computer, the nozzle runs according to the two-dimensional data of the model section, and selectively sprays the adhesive at the corresponding position to finally form the layer.

After each layer is bonded, the forming cylinder is lowered by a distance equal to the thickness of the layer, and the powder supply cylinder rises a certain height to push out the excess powder, which is pushed by the powder spreading roller to the forming cylinder, and then it is leveled and compacted. This cycle is repeated until the bonding of the entire object is completed.

If you want to know more, please click:

✌️✌️✌️